Leonova Diamond® is a portable instrument for condition measurement in rough industrial surroundings. Wherever measuring route efficiency is a priority, Leonova Diamond is the perfect choice, providing a powerful combination of well-proven measuring techniques for every situation all in one instrument.

Lexical definition: di·a·mond \’dī-(ə-)mənd\ The hardest naturally occurring substance known; also the most popular gemstone. The durability, strength, and versatility of this precious stone inspired us to name the instrument Leonova Diamond.

THE DIFFERENCE IS IN THE DATA

ENGINEERED FOR PERFORMANCE

PRODUCTIVITY AND EFFICIENCY

UNIQUE CONDITION MONITORING EFFICIENCY

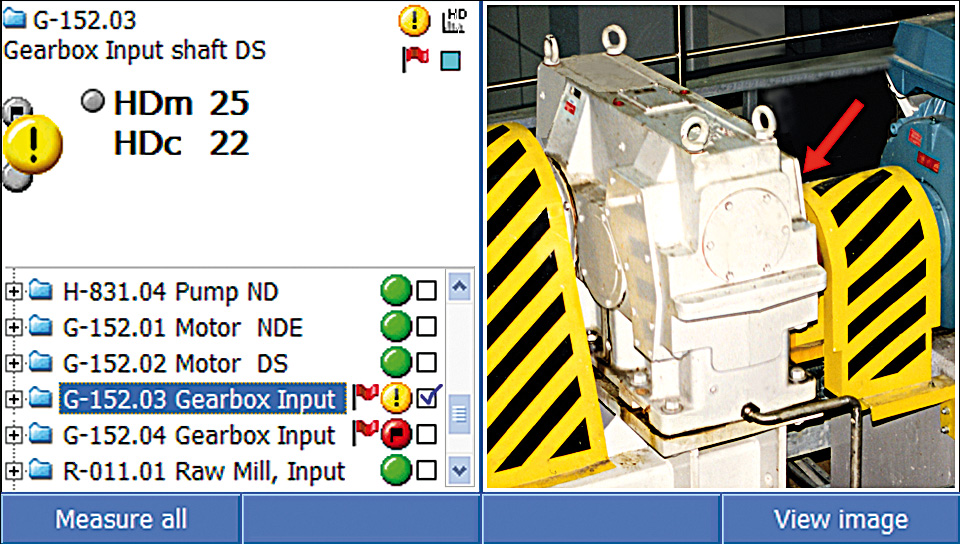

Leonova Diamond is a dependable and highly potent analysis tool, addressing all of your condition monitoring needs. It offers a full and wide range of sophisticated measuring techniques as well as all the supporting diagnostic and troubleshooting capabilities. The instrument efficiently and reliably handles different machine characteristics and variable running conditions. State-of-the-art digital technology and careful software design enable superior data acquisition and processing. For use in hazardous areas and hostile environments, an intrinsically safe version is available.

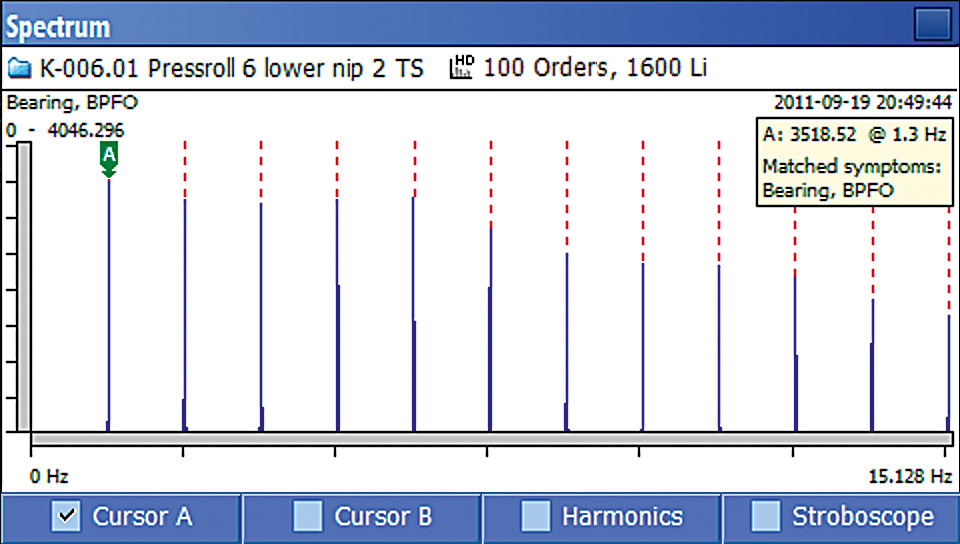

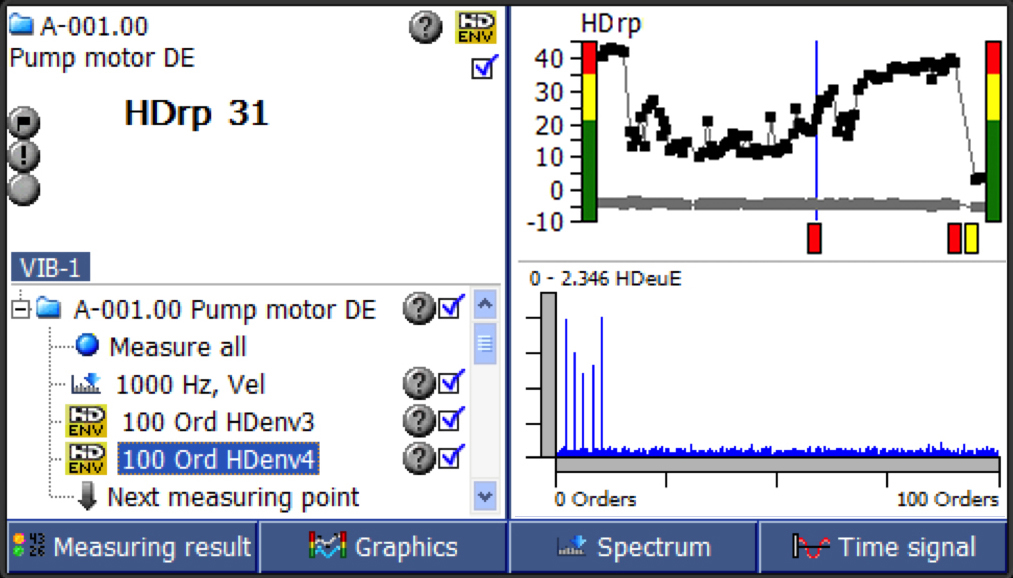

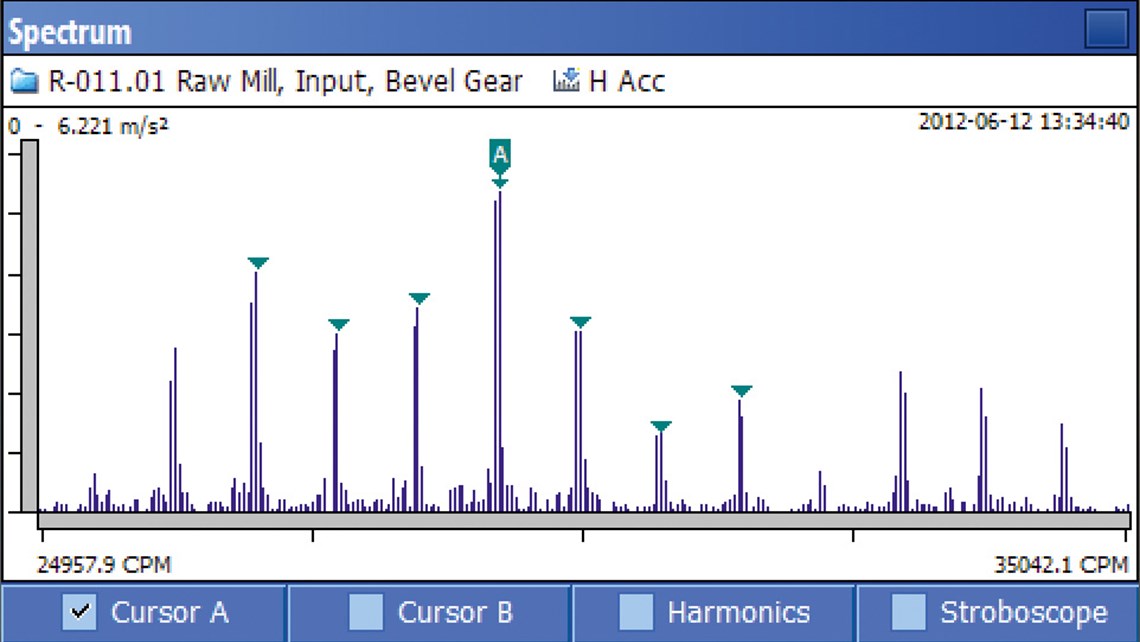

Leonova Diamond offers highly sophisticated vibration measurement and shock pulse measurements with the patented HD technologies, providing razor-sharp spectrums even where signals are weak and low in energy content. The instrument’s excellent signal-to-noise ratio gives a decisive advantage where weak signals are present among stronger signals, such as in gearboxes.

Leonova Diamond is part of the Leonova line of portable instruments and sibling to Leonova Emerald®.

QUOTES FROM OUR CUSTOMERS

“We were looking for a supplier who could solve the specialized problems of our clients regarding slow turning machinery. We also wanted a software platform that was analysis friendly. But the most principal factor in our decision to buy the Leonova Diamond was the HD technology. It will allow us to provide better service for our clients.”

Bárður Heinason, Machine technician, MEST Shipyards

NEED AN EX-CERTIFIED INSTRUMENT?

By clicking “Submit”, you agree that your message and personal details will be sent by email to relevant recipient(s) at SPM Instrument. You hereby also agree that SPM Instrument and its subsidiaries will have access to the information you have provided and that these data will be stored on our email server. The data will not be saved in any other way. We will not use this information to contact you about matters other than those specified in your request. We will not share your information with third parties.

Features

Leonova Diamond includes High Definition Shock Pulse Method (SPM HD®) for bearing condition and advanced three-channel vibration analysis for general machine condition and many more features, see below.

Bearing and lubrication condition

Note: Also read about HD ENV® (below) for bearing monitoring.

The SPM HD® method (HDm/HDc)

SPM Spectrum™

dBm/dBc

The original Shock Pulse Method is based on dBm/dBc which counts the rate of incoming shock pulses per second and provides one value for the shock carpet level and one value for the maximum level (peaks).

LR/HR

The LR/HR method was developed from the original Shock Pulse Method for condition diagnosis of rolling element bearings and allows a precision analysis of oil film condition in the rolling interface.

Vibration analysis

The HD ENV® technique

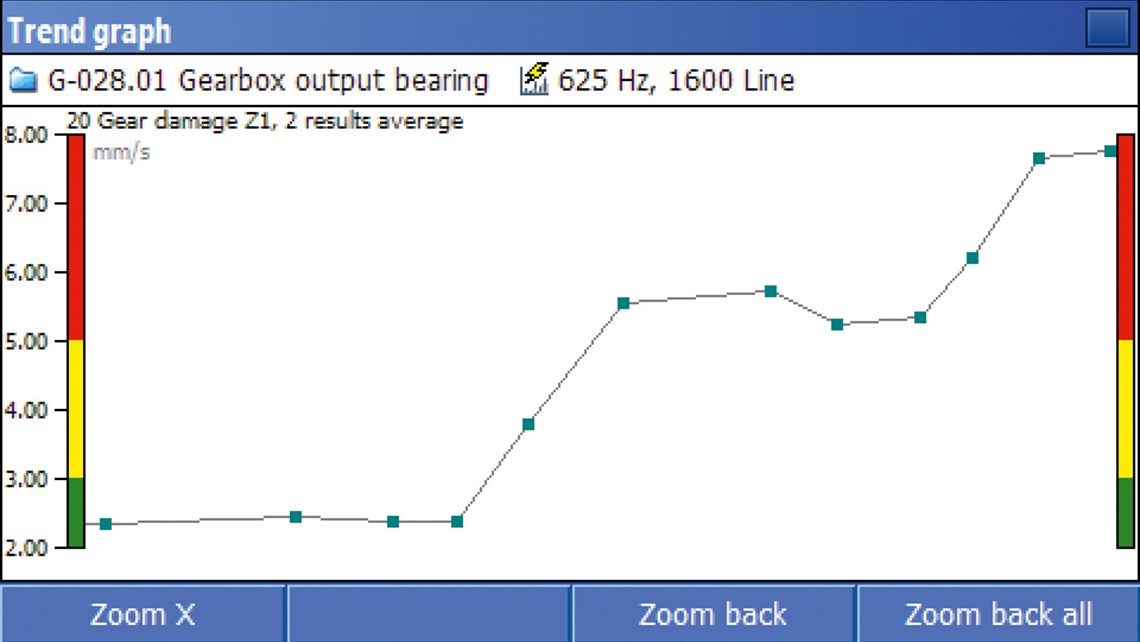

HD ENV® is a patented enveloping technique used for early detection of impact-related events such as gear and bearing damage. A number of predefined filters are available for easy selection; each designed to detect damages in different failure stages. The method utilizes cleverly engineered algorithms for digital signal processing to obtain optimal data for trending purposes.

Vibration severity plus FFT Spectrum

Measurement of vibration velocity, acceleration and displacement (0-40kHz frequency range) according to the latest ISO 10816 standards helps to diagnose general machine condition. In addition to the RMS vibration readings, the instrument displays an FFT spectrum, where symptoms of imbalance, misalignment, and structural weakness are easily identified.

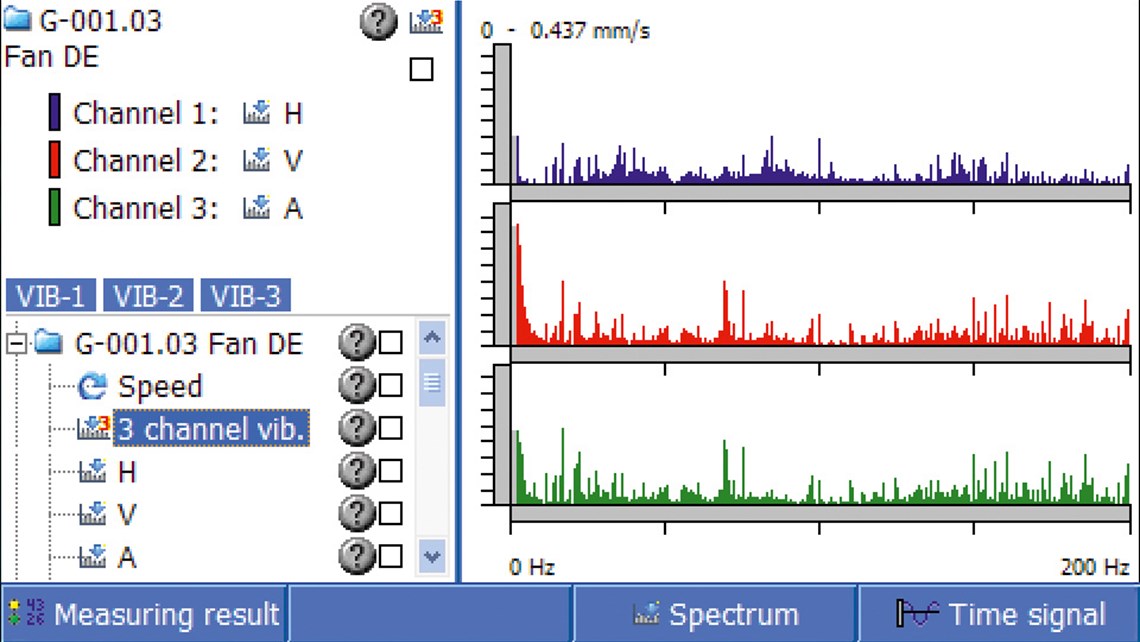

Three-channel vibration analysis

Three-channel vibration measurement allows you to study machine movement in three dimensions by observing the difference of the phase angles measured on the three channels. The three channels measure simultaneously, which means fast operation and rapid evaluation of assignments.

Corrective maintenance

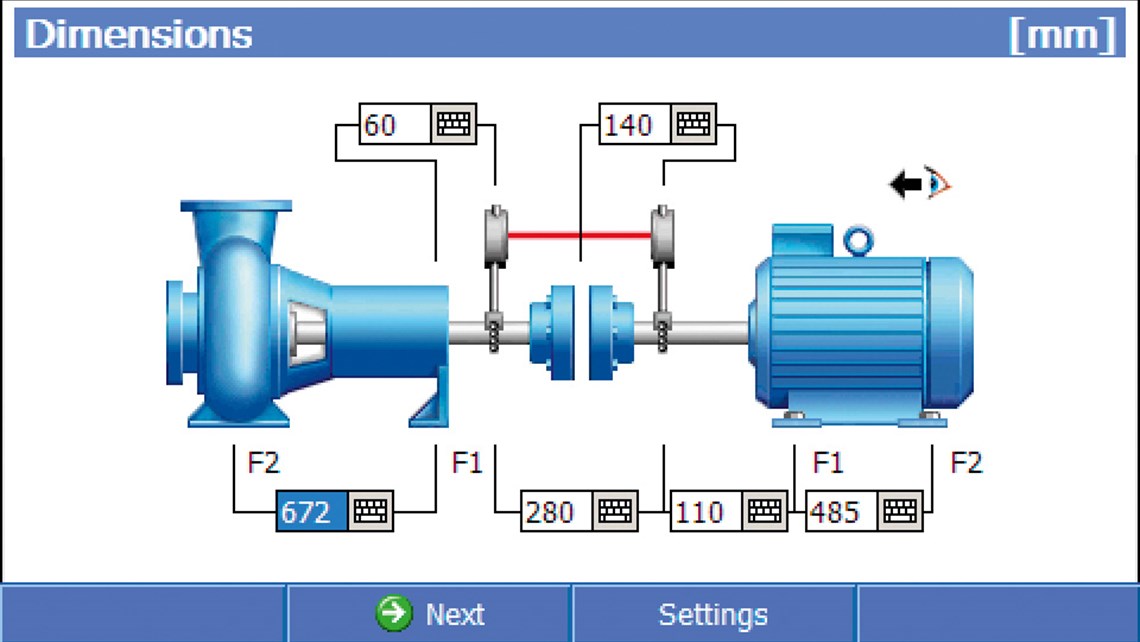

Precision shaft alignment

For laser alignment of horizontal and vertical machines, the optional LineLazer Alignment Kit connects wirelessly to Leonova Diamond, and the user is guided through the alignment procedure to a perfect result.

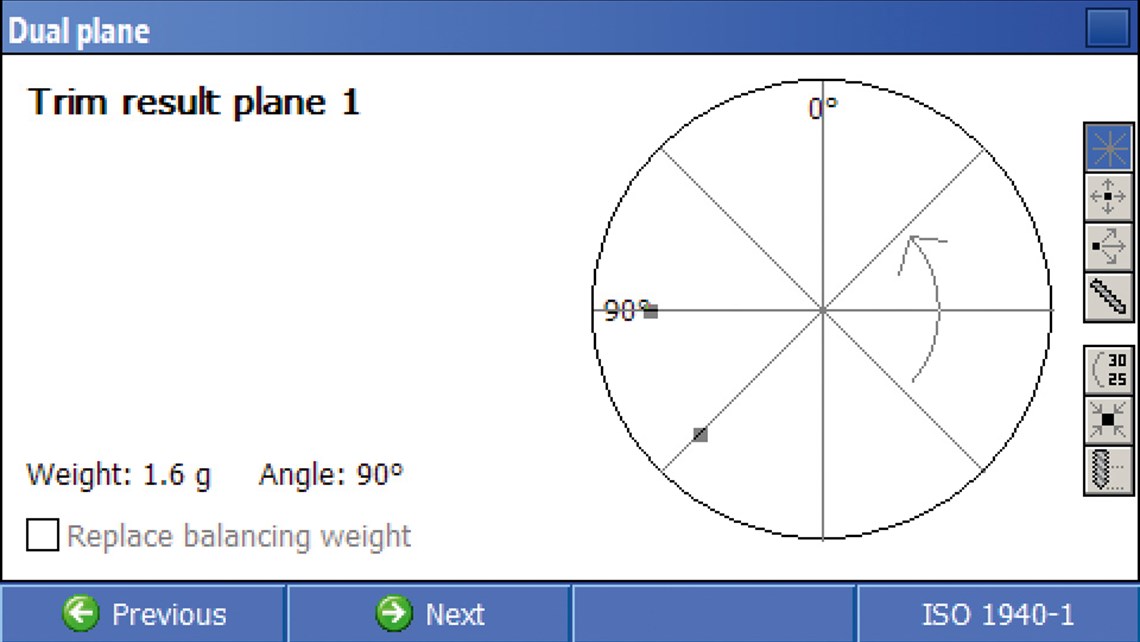

Dynamic balancing

Field rotor balancing in single and dual plane according to ISO 1940-1 standard with an initial vibration measurement guiding the user through a balancing procedure with suggestions for correcting the imbalance.

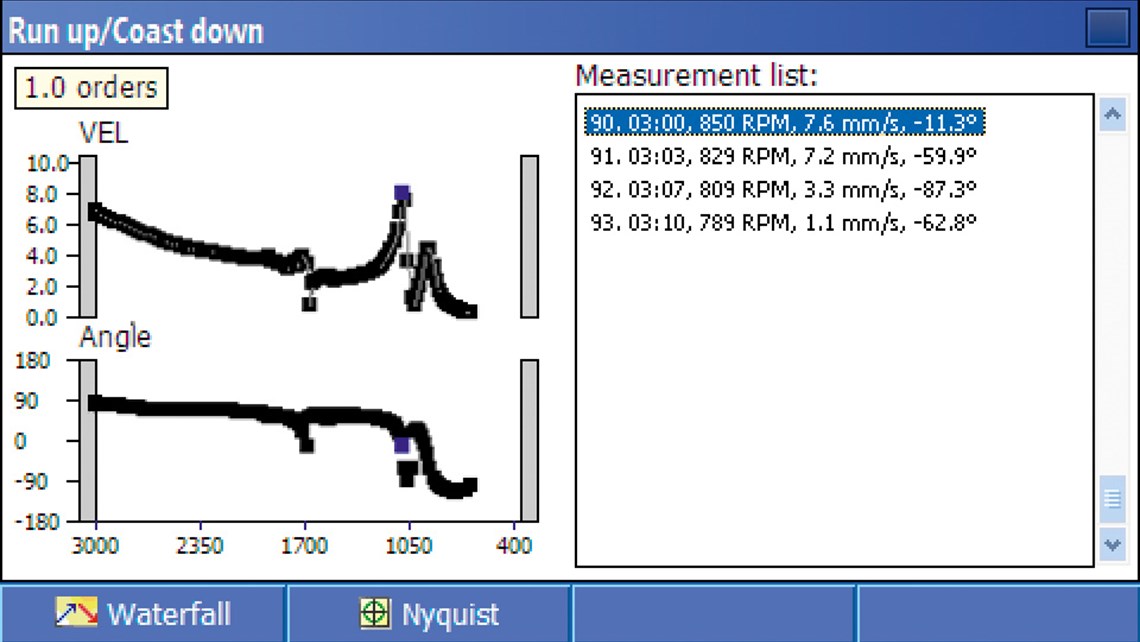

HD Order Tracking

On machinery operating under variable speed, vibration analysis with HD Order Tracking provides reliable data and crystal clear measuring results even when RPM varies greatly during the course of measurement. Order Tracking is applicable in a very wide RPM range, from just a few to thousands of revolutions per minute.

Technical overview

Instrument

Dimensions: 297x130x69 mm

Weight: 890 g

Display: TFT colour, 480x272 pixels, 4.3 inch widescreen, adjustable backlight

Instrument modules

Platform always included for unlimited use

- Platform function: SPM HDm/HDc and/or SPM LR/HR

- RMS vibration, ISO 2372

- Speed measurement

- Temperature measurement

- Stethoscope function

- Analog signals, current and voltage

- Time signal recording

- Measuring point identification with CondID® memory tags

- Automatic recording, up to 50 hours

- Checkpoints, free text

- Recording of vocal comments

- Supports 2 channel simultaneous vibration measurements

- Supports up to 12 800 lines, 20 kHz

Functions for unlimited or limited use

Unlimited and limited functions can be combined at will.

- SPM HD Expert, time and frequency domain analysis

- Shock pulse method HDm/HDc

- Shock pulse method dBm/dBc

- Shock pulse method LR/HR

- SPM Spectrum

- Vibration ISO 10816 with spectrum

- Vibration ISO 20283-5

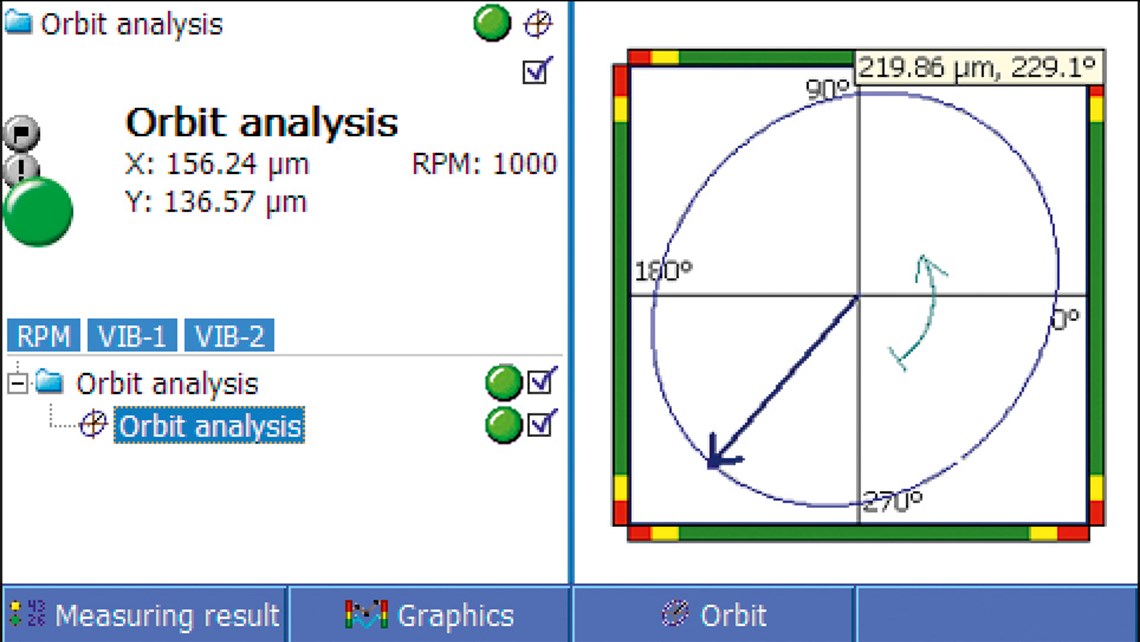

- Orbit analysis/Shaft centerline plot

- 3 channel simultaneous vibration

- Vibration Expert

HD Order Tracking

Time signal and 25 600 lines/40kHz

HD ENV

EVAM evaluated vibration analysis

Post trigger

Run up/coast down

Bump test

Frequency Response Function (FRF) - Vibration Advanced

HD Order Tracking

Time signal and 12 800 lines/20kHz

HD ENV

FFT spectrum with symptoms

Post trigger - HD Analysis

Vibration Expert

SPM HD Expert - Balancing, single and dual plane

- Shaft alignment

Accessories and packages

PORTABLE INTELLIGENCE IN CONVENIENT PACKAGE SOLUTIONS

With price cuts up to 30% off unbundled prices during this special offer, there has never been a better time to upgrade to this heavy-duty, high-performance instrument. Leonova Diamond® brings powerful analysis and troubleshooting capabilities to your condition monitoring program, and smart, superior-quality data to your IoT and Big Data systems.

This user-friendly data analyzer enables high-efficiency measuring routes with instant condition evaluation in green-yellow-red. Packages include the comprehensive software Condmaster Ruby® for further analysis of measurement data.

Basic

- Leonova Diamond handheld instrument

- Charger

- Communication cable

- Tacho/temperature probe

- Vibration transducer

- Magnet foot

- Measuring cable

- Carrying case, soft

- Analysis and diagnostic software

Condmaster Ruby

- Measuring techniques:

VIB ISO 10816 + Spectrum

![]()

Advanced

- Leonova Diamond handheld instrument

- Charger

- Communication cable

- Shock pulse and tacho/temperature probe

- Vibration transducer

- Magnet foot

- Measuring cable

- Quick connector, DuoTech

- Carrying case, hard

- Analysis and diagnostic software

Condmaster Ruby

- Measuring techniques: VIB ISO 10816 + Spectrum, Vibration Expert

Expert

- Leonova Diamond handheld instrument

- Balancing equipment

- Charger

- Communication cable

- Shock pulse and tacho/temperature probe

- Three vibration transducers

- Three magnet feet

- Measuring cables including a 3-channel splitter

- Quick connector, DuoTech

- Carrying case, hard

- Headset with microphone

- Analysis and diagnostic software

Condmaster Ruby

- Measuring techniques: VIB ISO 10816 + Spectrum, 3-channel measurement, complete analysis functionality with HD Analysis and

VIB/SPM HD Expert, Balancing