Easy-Laser E960 - Turbine alignment

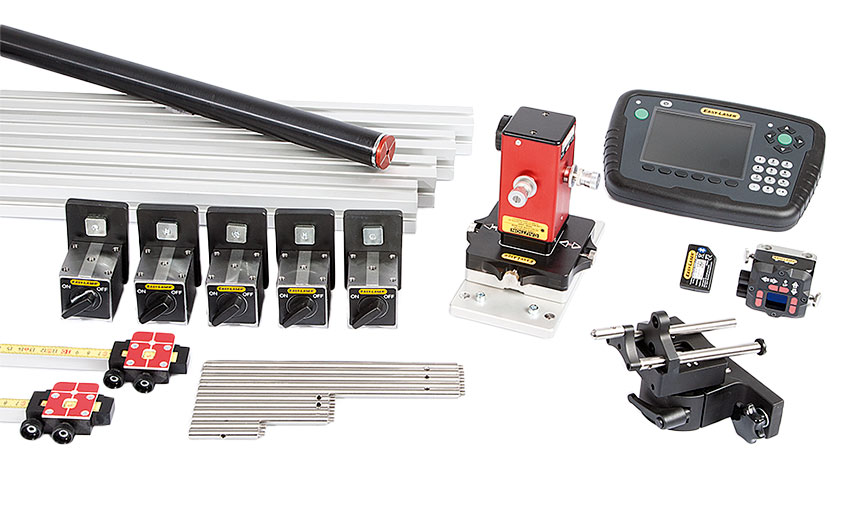

Easy-Laser® E960 Turbine alignment systems make the measurement and adjustment work of diaphragms and bearings easier thanks to the wireless detector unit and measurement programs that guide you through the measurement process.

All of the parts included in the systems are designed and built for even the most demanding workplace and easy setup on any machinery. The versatile design solves the straightness measurement problems quickly and with precision for any application. Objects up to 40 m (132 feet) can be measured. The detector reads measurement values with a resolution of 0.001 mm (0.05 mils).

Easy-Laser® E960-A and E960-B

The system comes in two versions. Easy-Laser® E960-A has a measuring probe with a stroke of 10 mm. The slidable tube makes it possible to measure several positions in a row without moving the bracket. Suitable for gas turbines and smaller steam turbines.

Easy-Laser® E960-B has a measuring probe with a stroke of 60 mm. This system is suitable for larger turbines. Software, laser transmitter and detector are common to the systems. The detector brackets differ.

Versatile programs

The straightness programs of system E960 are very versatile and let you work in a way that suits every job best. You can add, remove, and remeasure measurement points at any time during the measurement. The program can handle up to 999 points. You can include both full bores and half bores in any combination in one measurement; the program will calculate the correct centerline in all cases. The measurement program includes many different methods for straightness measurement: 1-point measurement, 4-point measurement, Multipoint measurement (also ovality measurement), 3-point measurement, 3-point measurement with arbitrary angles. Optionally a reference detector can be used to monitor the laser transmitter position at long distances.

The measurement result

Thanks to the large color display with clear graphs and measurement data, you can evaluate the result directly on site. Any point can be set as a reference and you can set an offset to which the centerline will be recalculated. You can also calculate waviness (short and long) and best-fit for the points. If you want, the result can also be checked against a tolerance value. The measurement system takes care of all these complicated calculations for you.